Learn the key steps to accurately determine your Return On Investment in reverse logistics and optimize your business strategies.

Key Takeaways:

1. Calculating ROI in reverse logistics is critical for organizations to assess the profitability and efficiency of their operations.

2. Businesses can calculate the return on investment in reverse logistics by following a step-by-step method and using ROI analysis tools.

3. Measuring critical indicators such as return rate, processing time, and salvage value aids in analyzing strategy performance and identifying improvement opportunities.

4. Continuous improvement through customer feedback analysis, collaboration with suppliers, and the implementation of technology solutions can help reverse logistics maximize ROI.

5. By pushing for improvement and exploiting data-driven insights, organizations may make more educated decisions, increase profitability, and see a good return on investment in reverse logistics.

Introduction to Return On Investment in Reverse Logistics

Reverse logistics is a critical part of supply chain management that deals with the return of products from customers to manufacturers and retailers. It includes processes like product returns, repairs, recycling, and disposal. Calculating the Return on Investment (ROI) in reverse logistics is critical for firms seeking to understand their operations’ financial performance.

In this blog, we’ll go over the important processes for effectively calculating your ROI in reverse logistics and optimizing your business tactics. Businesses can increase profitability and customer satisfaction by understanding ROI calculation components, using ROI analysis tools, monitoring the efficacy of reverse logistics techniques, and maximizing ROI through continuous improvement.

Understanding reverse logistics and Return On Investment

To calculate ROI in reverse logistics, you must first comprehend the concept and its significance. Reverse logistics refers to the full process of managing returned products, which includes transportation, sorting, disposition, and data analysis. It is critical to reducing the negative environmental impact of returns while increasing the recovery value of returned products.

ROI in reverse logistics analyzes the financial performance of these procedures and assists firms in determining the profitability of their reverse logistics activities. It considers elements such as the cost of reverse logistics operations, the value of returned products, and the savings realized through effective reverse logistics tactics.

Key Components of Return On Investment Calculation in Reverse Logistics

Calculating ROI in reverse logistics involves several critical components:

1. Cost of reverse logistics operations: This comprises expenses for transportation, personnel, warehousing, and administrative costs connected with return management.

2. Value of returned products: This is the possible resale or salvage value of the returned items. In order to compute ROI, the value of returned products must be precisely determined.

3. Cost savings via efficient reverse logistics techniques: Efficient reverse logistics tactics can help firms save money while increasing the value of returned products. These savings add to the overall ROI.

Businesses can evaluate their ROI in reverse logistics by taking into account these factors and conducting the relevant calculations.

How is return on investment (ROI) calculated?

Calculating ROI in reverse logistics is crucial for firms seeking to streamline operations and increase profitability.

To effectively calculate ROI, firms must first understand the main components, such as the expenses of reverse logistics operations, the value of returned products, and the savings realized through efficient tactics.

Measuring reverse logistics efficacy through measures such as return rate, processing time, and salvage value is essential for evaluating performance and identifying areas for improvement.

Continuous improvement in reverse logistics requires analyzing consumer input, collaborating with suppliers, and using technology solutions to optimize ROI.

To improve financial performance and customer happiness in reverse logistics, organizations can follow these measures and strive for continuous improvement.

Illustration 1

Step 1: Determine the investment.

Let’s say a company invested $100,000 in a reverse logistics project. This investment includes costs associated with equipment, transportation, labor, and any other expenses incurred during the project.

Investment = $100,000

Step 2: Calculate the total recovered value.

Next, we need to calculate the total recovered value, which represents the value obtained from the reverse logistics process. This could include the resale value of refurbished products, the salvage value of returned items, or any other financial gains from the reverse logistics initiative.

Let’s assume that the total recovered value is $50,000.

Total Recovered Value = $50,000

Step 3: Calculate Cost Savings

In addition to the recovered value, reverse logistics initiatives often result in cost savings. This could include reduced waste disposal costs, lower transportation expenses, or any other operational efficiencies achieved.

Let’s assume that the cost savings from the project amount to $25,000.

Cost savings = $25,000

Step 4: Calculate the net return.

Now, we can calculate the net return by adding the total recovered value and the cost savings.

Net Return = Total Recovered Value + Cost Savings

= $50,000 + $25,000

= $75,000

Step 5: Calculate ROI

Finally, we can calculate the ROI using the formula: ROI = (net return/investment) x 100.

ROI = ($75,000 / $100,000) x 100

= 0.75 x 100

= 75%

Step 6: Interpret the ROI

The calculated ROI is 75%. This means that for every dollar invested in the reverse logistics project, the company earned a return of 75 cents. This indicates a positive ROI, suggesting that the project has been profitable and provided a return on the initial investment.

Please note that this example and the values used are for illustrative purposes only. The actual ROI calculation would depend on the specific circumstances and financial data of the reverse logistics project.

Implementing Return On Investment Analysis Tools

Businesses can use a variety of analytical methods to accurately assess ROI in reverse logistics. These technologies assist in the collection and analysis of data relating to reverse logistics activities, returned products, and associated expenses. Some commonly used ROI analysis tools are:

1. Return rate analysis: This tool assists in determining the percentage of products returned by customers and the causes of returns. It provides insights into areas for improvement.

2. Cost tracking software: This software helps firms track and monitor the costs connected with reverse logistics operations. It assists in identifying areas of excessive expenditure and executing cost-cutting initiatives.

3. Data analytics tools: These tools evaluate data generated during reverse logistics activities and provide useful insights. They assist in spotting trends, patterns, and areas for improvement.

Businesses that use these ROI analysis tools can acquire a thorough insight into their reverse logistics operations and make informed decisions to maximize their ROI.

Measuring the Effectiveness of Reverse Logistics Strategies

Measuring the efficiency of reverse logistics techniques is critical for calculating ROI appropriately. It entails analyzing the effectiveness of various tactics used in reverse logistics operations. Some important metrics to consider while evaluating the effectiveness of reverse logistics techniques are:

1. Return rate: This metric represents the percentage of products returned by customers. A lower return rate suggests more efficient reverse logistics tactics.

2. Processing time: This indicator tracks the time it takes to process returned products and make them accessible for resale or disposal. Efficient processing lowers costs and increases ROI.

3. Salvage value: This indicator assesses the value gained by reselling or salvaging returned products. Maximizing salvage value with appropriate strategies increases ROI.

Businesses can improve ROI by frequently measuring and analyzing this data.

Optimizing Return On Investment through continuous improvement

Continuous improvement is an important part of optimizing ROI in reverse logistics. Businesses can increase their ROI by regularly assessing and improving their reverse logistics procedures. Here are some ways for continual improvement:

1. Customer feedback analysis: Analyzing customer feedback on returns can reveal useful insights into areas for development. Addressing customer issues and executing appropriate modifications might result in a higher ROI.

2. Collaboration with suppliers: Working with suppliers can help to streamline reverse logistics procedures and cut expenses. Strong supplier partnerships can lead to increased efficiency and return on investment. Strong supplier partnerships can lead to increased efficiency and return on investment.

3. Using sophisticated technology solutions: Automated sorting systems, inventory management software, and data analytics tools can help optimize reverse logistics operations and increase ROI.

Businesses that strive for continual development and adopt these tactics can maximize their ROI in reverse logistics.

Conclusion:

To summarize, evaluating ROI in reverse logistics is an important step for firms looking to improve their financial performance and customer happiness. Companies may optimize their operations and increase profitability by understanding the essential components, applying ROI analysis tools, monitoring strategy effectiveness, and constantly pushing for improvement. The step-by-step process detailed in this article gives a clear path for organizations to use when calculating their ROI in reverse logistics. By adhering to these rules and employing data-driven insights, organizations can make educated decisions, discover areas for improvement, and eventually achieve a favorable return on reverse logistics investments.

FAQ

What is the Return On Investment in logistics?

In logistics, return on investment (ROI) is critical for assessing the success and profitability of reverse logistics operations.

Metrics such as return rate, processing time, and salvage value assist businesses in measuring performance and identifying opportunities for improvement.

To calculate ROI, subtract the cost of reverse logistics from total sales and then compute the net profit. Companies can calculate ROI by dividing net profit by total costs and reporting the result as a percentage.

This percentage represents the ROI for reverse logistics activities, reflecting their success and efficiency.

To maximize ROI in reverse logistics, apply ROI analysis tools, track strategy effectiveness, and strive for continuous improvement.

Businesses can enhance profitability by adopting a data-driven approach and focusing on improving operations. and customer satisfaction in the reverse logistics process.

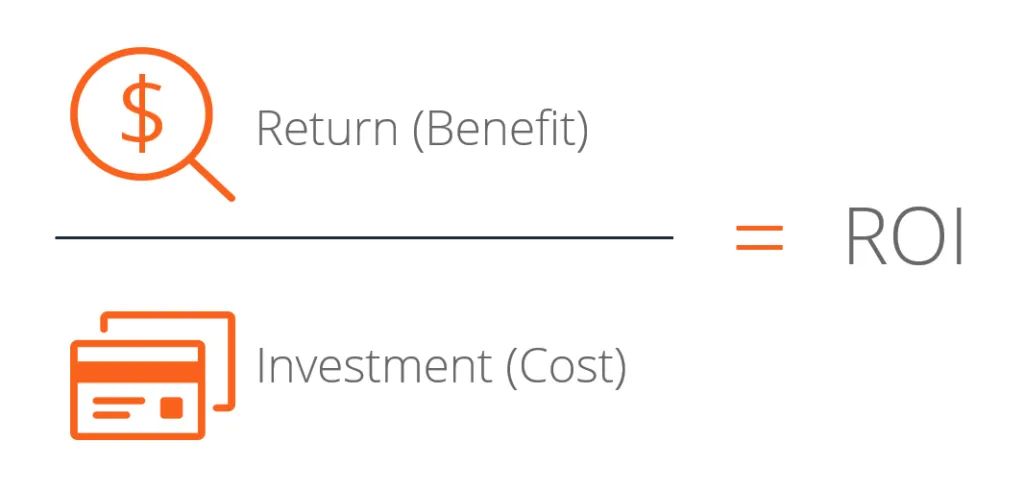

What is the general formula for Return On Investment?

Return on investment (ROI) in logistics is an important indicator for firms evaluating the profitability and effectiveness of their reverse logistics activities.

Companies can compute ROI step by step, determining the return obtained for every dollar invested in reverse logistics.

The net profit is calculated by subtracting the total cost from the total income, dividing by the total cost, and expressing it as a percentage.

This percentage represents the success and efficiency of operations, with a higher ROI suggesting a more successful investment.

Check out our previous blog post by clicking here: